The much-anticipated annual launch of Loch Gorm is finally here! Named after the famously dark, peaty loch overlooked by the distillery, our annual Loch Gorm limited edition is our only regular expression matured entirely in oloroso sherry casks.

The 2024 edition was distilled in 2014 and matured in oloroso sherry butts previously used by Bodega José y Miguel Martín. The majority of fresh casks in the vatting allow for layers of oloroso influence to be imparted from the sherry soaked oak.

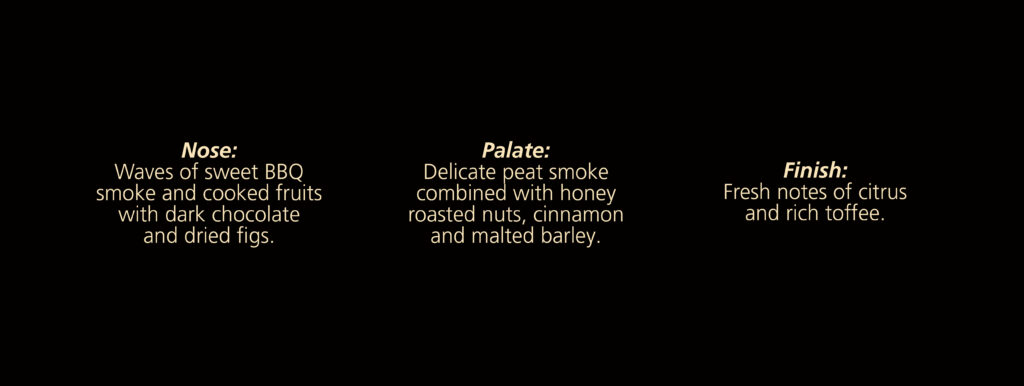

“Loch Gorm has often been our most sought after limited edition and I don’t see that changing in 2024. Distilled in 2014, these sherry butts have given this year’s release an abundance of rich spices and toffee notes. A great example of peat and sherry working in harmony together,” Anthony Wills, Kilchoman Founder.

Loch Gorm 2024 will be available from your local stockists in the UK and across the world from this week. For those of you who live in countries further away, bottles may take a few more weeks to find themselves on shelves.

For more information please email admin@kilchomandistillery.com

Anthony & Kathy travelled to Jerez to meet our sherry cask supplier, Jose y Miguel Martín. Click here to read more.